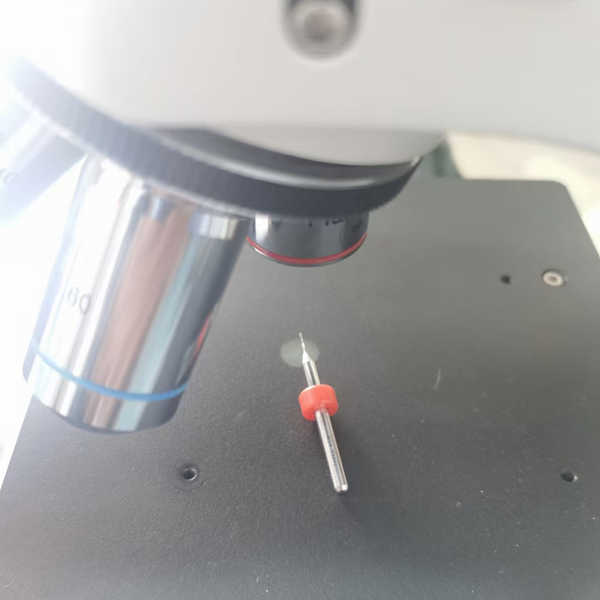

smartplasma solves the problem of residual glue residue in the needle groove after drilling the FPC drill needle. First of all, let’s take a look at the drill needle in the FPC industry, the special drill needle for FPC soft board, including the needle handle and the needle body located at one end of the needle handle. The needle body is far away One end of the needle handle is a conical tip, the needle body is symmetrically provided with two spiral chip flutes along the body direction to the tip, and a non-sharpened back edge is formed between the two chip flutes. Belt, the junction between the two chip flutes and the tip forms a main cutting edge, the conical bottom of the tip is located between the two chip flutes to form a secondary cutting edge, and the needle shank is provided There is a rotating shaft, and a C-shaped support rod is connected to the rotating shaft. The other end of the C-shaped support rod is provided with a drying device. The drying device includes a box body and a hair dryer. The box body includes a box body and a box cover. It is connected to the box body through a hinge. The box body is fixed with a horizontal pallet on the inner walls of the left and right sides. The rear wall of the box body has an inwardly protruding air inlet device, and the air outlet of the blower is sleeved on the air inlet device. Inside, a drill pin disc is arranged in the box body.

處理前效果圖

With the continuous use of the drill bit, there will be glue in the groove of the drill bit, which is more troublesome to handle. Guoxing technology smartplasma can etch the micro-holes to help solve the problem of residual glue in the needle groove after drilling the drill bit FPC. Plasma processing technology is a specific application of the special properties of plasma: the plasma processing system generates plasma by setting two electrodes in a sealed container to form an electric field, and a vacuum pump is used to achieve a certain degree of vacuum. As the gas becomes thinner and thinner, the molecular spacing And the free movement distance of molecules or ions is getting longer and longer. Under the action of electric field, they collide to form plasma. These ions are very active and their energy is enough to break almost all chemical bonds and cause chemical reactions on any exposed surface. , Plasma of different gases has different chemical properties. For example, plasma of oxygen has high oxidizing property and can oxidize photoresist to react to generate gas, so as to achieve the cleaning effect; plasma of corrosive gas has good various properties. Anisotropy, so that it can meet the needs of etching.

處理后效果圖

Corresponding to different materials, use the corresponding gas combination to form a strong etching gas-phase plasma and chemical reaction and physical impact with the body of the material surface, so that the solid material on the surface of the material body is vaporized to generate gases such as CO, CO2, H2O, etc. , So as to achieve the purpose of micro-etching. Smartplasma solves the problem of residual glue residue in the needle groove after FPC drilling. The main features: uniform etching without changing the characteristics of the material matrix; it can effectively roughen the surface of the material and accurately control the amount of microetching. The plasma surface treatment machine achieves PBC removal of surface glue by plasma bombarding the surface of the object. PCB manufacturers use the etching system of the plasma cleaning machine to decontaminate and etch to remove the insulators in the boreholes, and ultimately improve the product quality.

Consult now