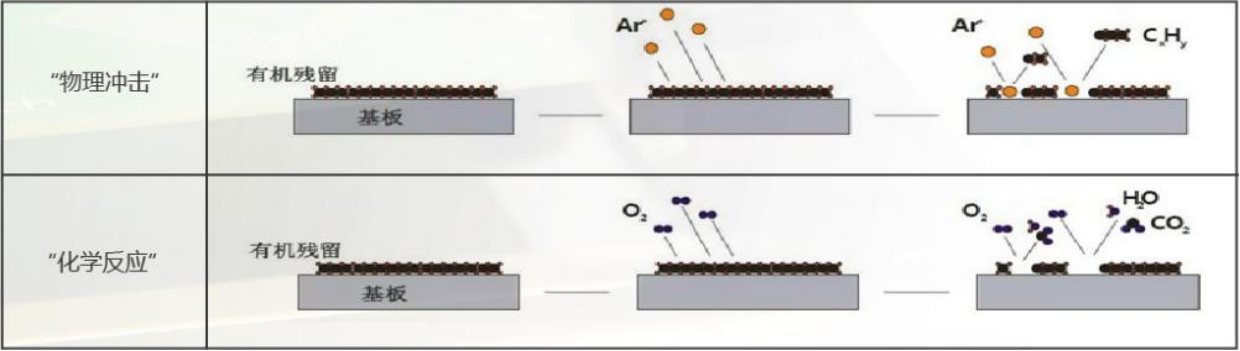

GX-1000 atmospheric plasma surface treatment equipment design ideas, Guoxing technology talked about in fact, in the process of processing objects with low-temperature plasma, various positive and negative ions in the plasma gas, high-energy and high-speed moving electrons, heavy Particles, etc. will have physical and chemical reactions on the surface of the material to be treated, so the four (or five) effects of the low-temperature plasma surface treatment mentioned above usually occur at the same time.

According to the customer's requirements for the surface cleaning treatment of materials, the design and development of the low-temperature plasma treatment program and the design of the treatment device are mainly designed to clean and activate the surface of the material, increase the surface cleanliness and the hydrophilicity of the material. This is the design of this project. Prerequisites that must be considered.

In the design of the device, it is necessary to consider that more materials can be placed and processed at the same time to meet the efficiency of mass production. The overall uniformity of the processing effect of the processing device is also a necessary and sufficient condition to be considered.

On the premise of ensuring that the above treatment effects and requirements are met, the design of the device must also consider a good performance-to-price ratio, safety, reliability, and durability, and minimize daily maintenance costs.

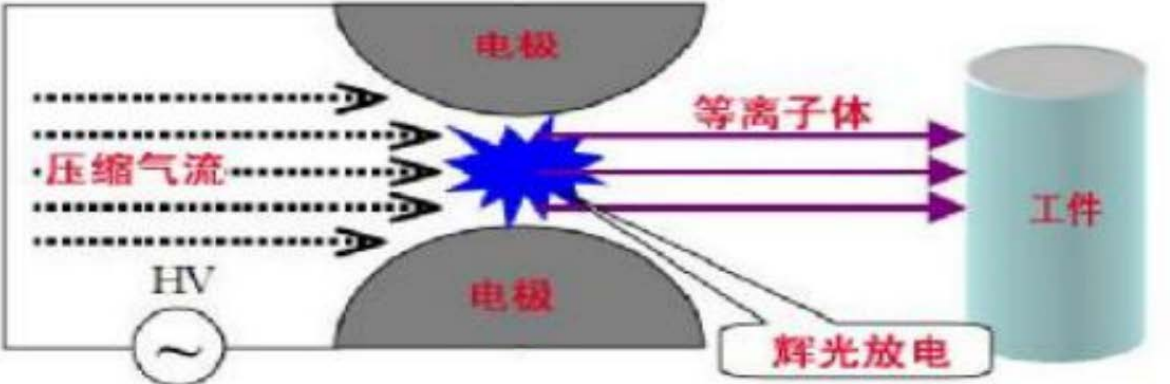

The schematic diagram of the plasma surface treatment device of this scheme

The GX-1000 atmospheric plasma surface treatment equipment is designed mainly from the following aspects: Surface cleaning method We know that in the vacuum plasma chamber, the object undergoes a radio frequency power supply to generate a high-energy disordered plasma under a certain pressure, and the surface of the product is cleaned by the plasma to achieve the cleaning purpose. Object surface activation treatment method The objects after the plasma surface treatment machine have enhanced appearance performance, hydrophilicity, and improved adhesion and adhesion. Surface etching treatment method The surface of the data is selectively etched by the reactive gas plasma. The etched data is converted into a gas phase and discharged by the vacuum pump. The processed data has an increased microscopic area than the surface and has outstanding hydrophilicity.

Consult now