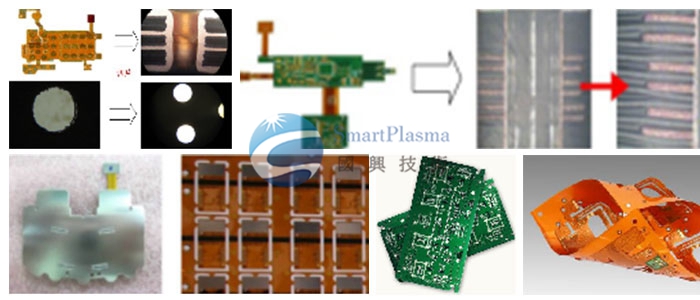

1. Removal of scum from multilayer flexible boards: suitable for various glue systems such as epoxy resin (epoxy resin) and acrylic resin (acrylic resin). Compared with chemical syrup, it can remove gum residue more stably and thoroughly, and the yield can also be significantly improved. 2. Removal of glue residue on soft and hard board: completely remove glue residue to avoid the corrosion of the soft board PI by potassium permanganate solution, and the hole wall will corrode uniformly, which improves the reliability and yield of hole plating. 3. High aspect ratio FR-4 hard board microporous deslagging, high TG hard board deslagging: due to the expansion of the chemical solution, when the chemical solution is used to remove the slag, the solution cannot penetrate into the micropores, making the slag removal incomplete and plasma It is not limited by the size of the aperture, and the smaller the aperture, the more prominent the advantage. 4. Modified and activated the surface of the front hole wall of the Teflon high-frequency microwave board for copper sinking to improve the bonding force of the hole wall and the copper plating layer to prevent black holes after copper sinking; eliminate the high-temperature fracture and the copper of the hole Phenomenon such as hole blasting in the inner layer of the hole copper improves the reliability. 5. Before lamination of soft and hard boards, multi-layer high-frequency boards, multi-layer hybrid boards, etc., roughen the surface of PI, PTFE and other substrates: plasma treatment can remove surface foreign matter, oxide film, fingerprints, oil stains, etc., The surface can be dented and roughened, so that the bonding force can be significantly improved.

Tags:

Consult now